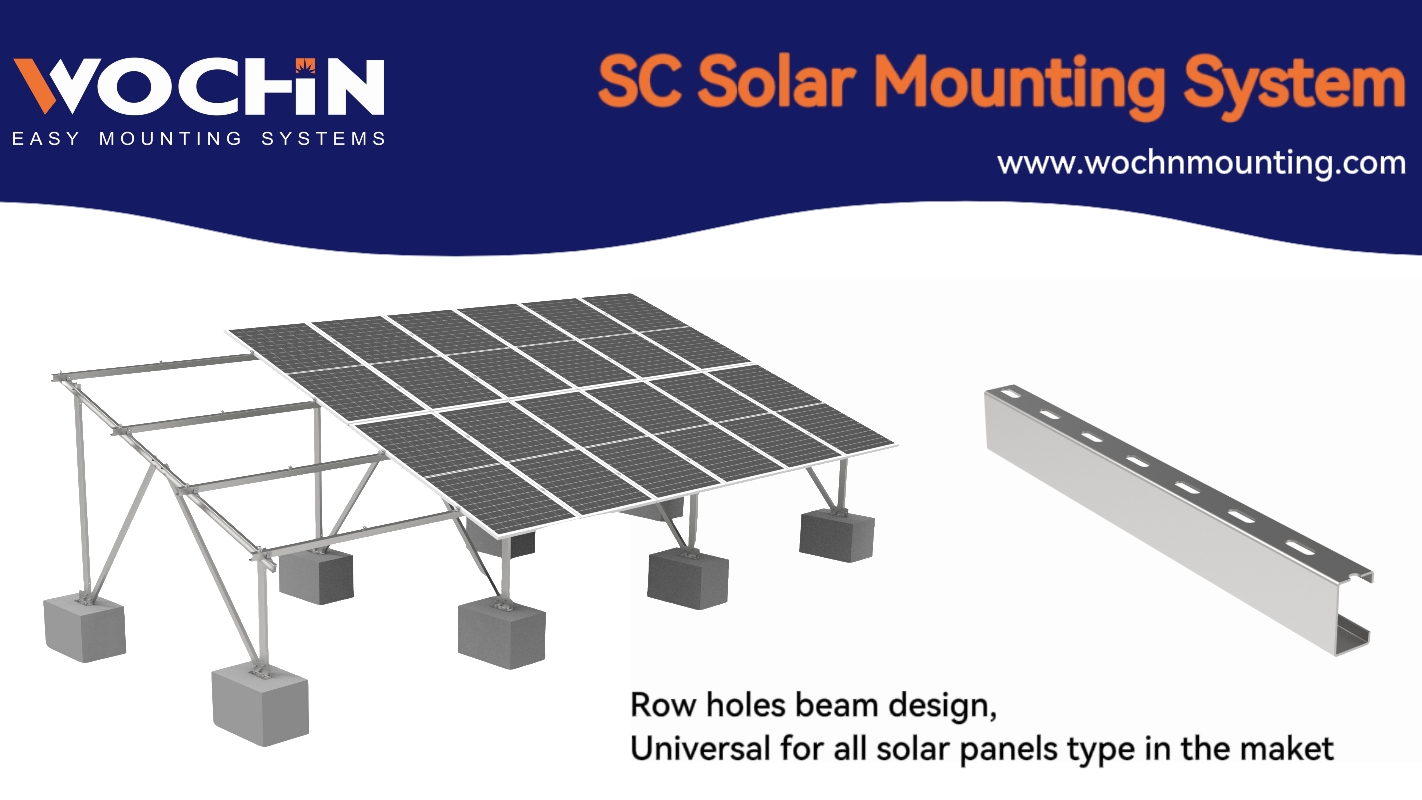

The WOCHN C-section steel ground system currently mainly includes the SC DP and SP series. WOCHN's C-section steel ground system adopts a modular design, allowing customers to customize it according to their specific needs, making it flexible for different construction projects. For example, the SC solar mount system can be combined and adjusted in various ways based on the customer's requirements. Particularly, for a recent order to South Africa, the additional perforated design greatly enhances the system's adaptability, enabling customers to easily adjust their inventory configuration and reduce inventory management complexity.

Why C-shaped steel becomes the choice of photovoltaic support bracket?

1. Our C-shaped steel is typically made from Q235B steel, with a surface hot-dip galvanized coating (zinc layer ≥ 60μm) or treated with a zinc-magnesium-aluminum corrosion-resistant coating (coating weight 275g). This provides excellent corrosion resistance, with a service life of over 25 years. The cold-bending forming process ensures strength, while also reducing material usage by 20%-30% compared to traditional H-steel or square steel.

2.The standardized design of C-shaped steel, particularly the standardized hole positions, simplifies the installation process. It can typically be assembled using bolts, eliminating the need for complex welding, saving both time and labor. Additionally, the length of C-shaped steel can be customized according to project requirements, reducing the need for on-site cutting and further lowering installation costs.

3. The cross-sectional shapes of C-shaped steel (such as C60, C75, C80, etc.) are designed to easily fit with photovoltaic module frames or clamp, ensuring precise and stable installation, which improves overall construction efficiency.

4. In terms of cost-effectiveness, C-shaped steel is more affordable than aluminum alloy brackets, and its installation costs are lower, making it ideal for large-scale projects to reduce costs. This has led to C-shaped steel brackets accounting for over 50% of the market share in distributed and ground-mounted solar power stations.

Have you noticed the recent C-steel practice in the Colombian project?

In the photovoltaic project in Colombia, the use of C-shaped steel piles demonstrated its highly efficient application in actual engineering. The project completed the installation of 2,755 C-shaped steel piles in just 45 days, while simultaneously accomplishing key milestone tasks such as land clearing, excavation, backfilling, and cable laying.

This case highlights the practical value of C-shaped steel support systems in large-scale ground-mounted solar power stations, especially their adaptability and efficiency in complex international projects.

Overall, WOCHN's C-section steel ground system has become the preferred solution for an increasing number of customers due to its outstanding performance, flexible design, low maintenance costs, and international service. If you have more specific needs, WOCHN can provide you with a customized solution.